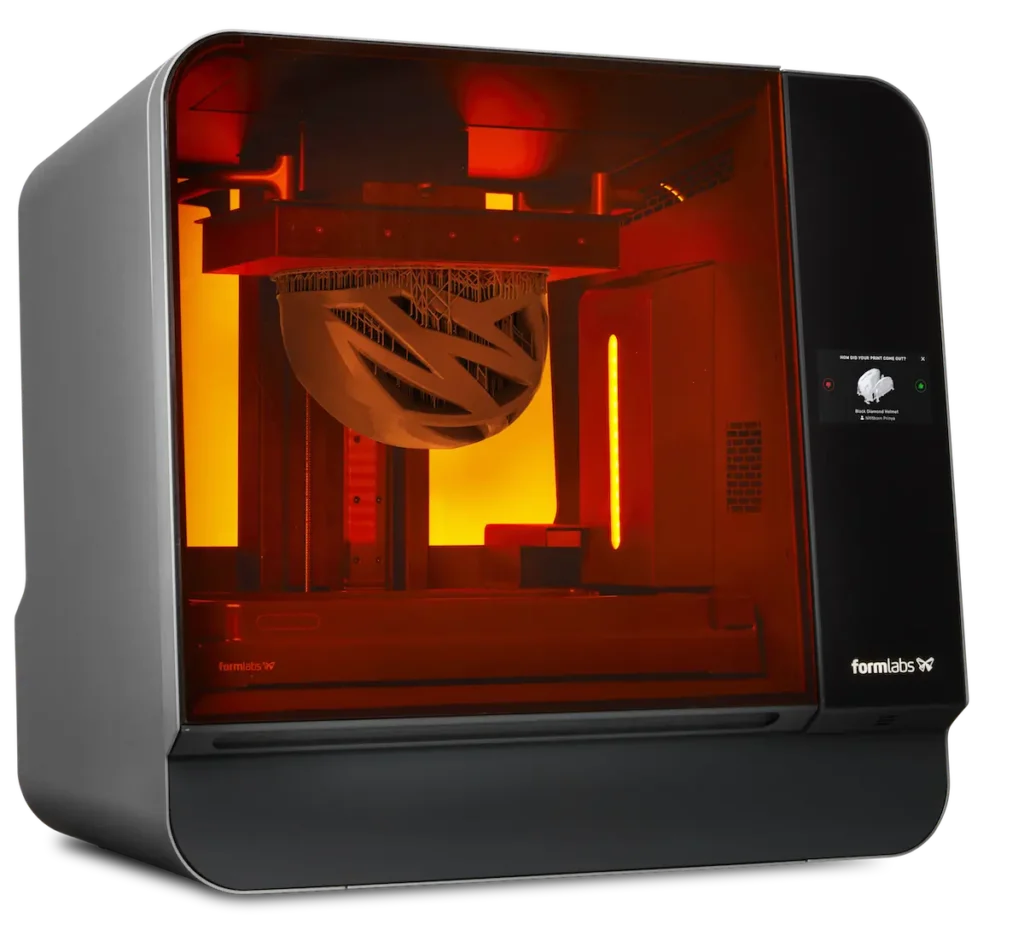

At Capa Esculturas, the combination of tradition and technology is the key to take our creations to the next level. Now, we have incorporated a Form 3L 3D printer from the renowned brand Formlabs. This advance represents a commitment to excellence, improving time and quality in our pieces.

Formlabs: Innovation in 3D Printing

Founded in 2011 in Massachusetts by visionaries from the MIT Media Lab, Formlabs is a pioneer in 3D printing technology. It is known for developing stereolithography (SLA) and selective laser sintering (SLS) printers, such as Form 1, Form 2, and the recent Form 3 and Form 3L.

The company has revolutionised the way artists and product designers develop their projects. Thanks to its capacity for innovation, it has made it possible to create 3D models for sculptures with an exceptional level of detail. Its advanced technology facilitates fast and accurate production, making Formlabs a global benchmark.

The Form 3L: Precision and Versatility

The Form 3L 3D printer is one of the most advanced of the fourth generation of SLA printers. Designed for demanding projects, it features low force stereolithography (LFS) technology, which provides a smoother, more detailed surface finish. It also has a print volume of up to 33.5 × 20 × 30 cm, ideal for resin 3D printing.

The Form 3L includes two 250 mW lasers and UV light to ensure high precision in every print. The modular design facilitates easy repairs and maintenance, ensuring it is always ready for the challenges of the shop floor. In addition, the self-generated, peel-off media simplifies post-processing, optimising times and ensuring a flawless surface finish.

This printer supports 23 industry-leading 3D printing materials, as well as others supported through Open Material Mode. This allows artists and designers to explore innovative materials, from specific resins to generic options that expand creative possibilities. In addition, the resin tank is designed to maximise process efficiency.

Impact on Our Creative Process

At Capa Sculptures, Form 3L has transformed our workflow. We can now create physical models from digital designs with exceptional quality. This eases the transition from prototypes to final sculptures. Advanced SLA printing reduces errors and improves the quality of our models, ensuring consistent results.

Thanks to this large format 3D printer, we produce high quality 3D prototypes and final parts with high precision in 3D printing. Its ability to work with different types of materials expands the possibilities for customisation. This approach also optimises production processes, allowing us to develop products more efficiently.

Use Cases: Sculpture Innovation

Form 3L has expanded our creative possibilities:

- Physical models from digital designs: We turn digital ideas into tangible prototypes with intricate details. This is key for 3D-printable materials, such as high-quality resins.

- Fast and accurate production: We can tackle complex projects in less time, without compromising on quality. Advanced SLA printing ensures a flawless surface finish.

- Additive manufacturing for sculptures: Large-scale designs are possible thanks to this large-format 3D printer.

- Customised prototypes: The flexibility in the use of resin 3D printer materials allows us to meet the specific needs of each client, from artistic projects to industrial applications.

Why we are committed to innovation

Formlabs technology allows us to improve our processes and excel in innovation in art workshops. By integrating this technology, we guarantee the production of sculptures with precision and quality. In addition, incorporating tools such as the Form 3L 3D printer optimises product development and ensures that every step of the process is efficient and controlled.

We are committed to staying ahead of the curve. That’s why tools like this are essential. They reflect our passion for combining art and technology.

The Future of 3D Printing in Layer Sculpture

The addition of this printer is just the beginning. We plan to continue exploring new technologies, to further innovate in the world of sculpture. With advanced tools and the support of product designers, we will continue to transform ideas into tangible pieces that transcend time.

Thanks to LosHacedores

We would like to thank LosHacedores, Formlabs Madrid’s marketing company, for their advice on the acquisition of this tool. Their professionalism was key in this process. For more information about them, visit their website.